Safety Survey

Safety Survey

Safety Survey

Specialist Services

Specialist Services

Specialist Services

(In partnership with IRT Consult)

(In partnership with IRT Consult)

(In partnership with IRT Consult)

Discover comprehensive safety and efficiency with our specialist services, in partnership with IRT Consult. Beyond our expert racking inspections, we offer a wide array of specialised services including VOC leak detection, Thermographic Inspections, and Compressed Air Leak Surveys.

Discover comprehensive safety and efficiency with our specialist services, in partnership with IRT Consult. Beyond our expert racking inspections, we offer a wide array of specialised services including VOC leak detection, Thermographic Inspections, and Compressed Air Leak Surveys.

Discover comprehensive safety and efficiency with our specialist services, in partnership with IRT Consult. Beyond our expert racking inspections, we offer a wide array of specialised services including VOC leak detection, Thermographic Inspections, and Compressed Air Leak Surveys.

Specialist Services - In partnership with IRT Consult

Specialist Services - In partnership with IRT Consult

As well as racking inspections, Safety Survey carry out all types of specialist services. Our services include VOC leak detection, Thermographic Inspections and Compressed Air Leak Surveys. Below we have detailed descriptions of all the specialist services we provide. If you would like more information on our racking inspection services then please contact us with your requirements.

As well as racking inspections, Safety Survey carry out all types of specialist services. Our services include VOC leak detection, Thermographic Inspections and Compressed Air Leak Surveys. Below we have detailed descriptions of all the specialist services we provide. If you would like more information on our racking inspection services then please contact us with your requirements.

As well as racking inspections, Safety Survey carry out all types of specialist services. Our services include VOC leak detection, Thermographic Inspections and Compressed Air Leak Surveys. Below we have detailed descriptions of all the specialist services we provide. If you would like more information on our racking inspection services then please contact us with your requirements.

Thermographic Inspection Services Leader, Worldwide

Thermographic Inspection Services Leader, Worldwide

Thermographic Inspection Services Leader, Worldwide

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

Applications

Applications

Applications

Infra-red Technology is being implemented across a range of industries and on a growing scale of applications.

Below is a list of the applications of our Thermographic Inspections. Click the corresponding numbered tab below to find out more information on each application.

Infra-red Technology is being implemented across a range of industries and on a growing scale of applications.

Below is a list of the applications of our Thermographic Inspections. Click the corresponding numbered tab below to find out more information on each application.

Infra-red Technology is being implemented across a range of industries and on a growing scale of applications.

Below is a list of the applications of our Thermographic Inspections. Click the corresponding numbered tab below to find out more information on each application.

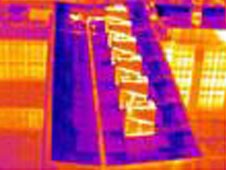

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

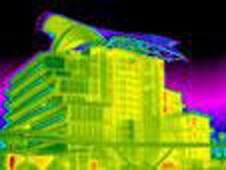

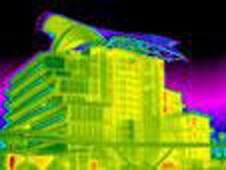

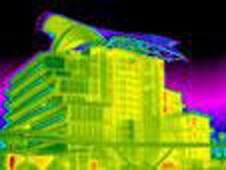

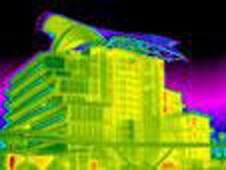

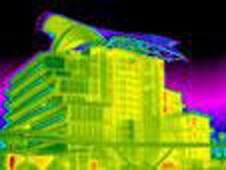

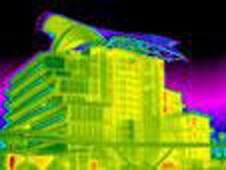

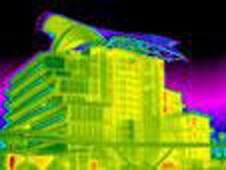

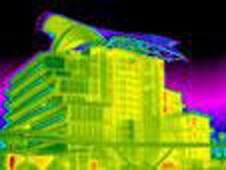

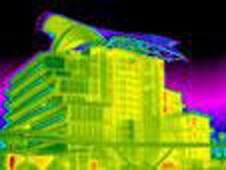

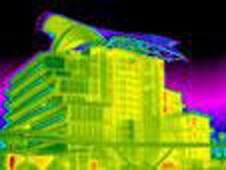

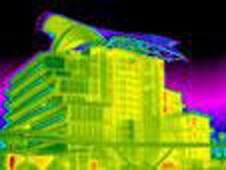

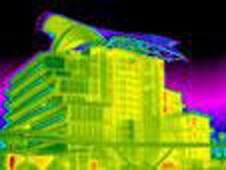

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems.

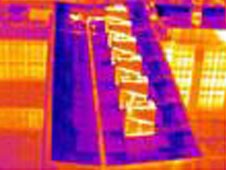

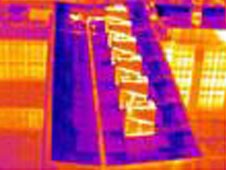

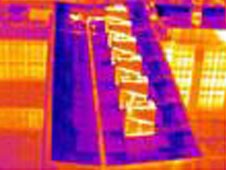

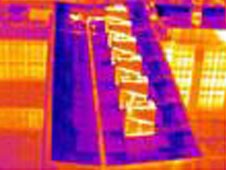

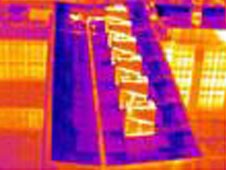

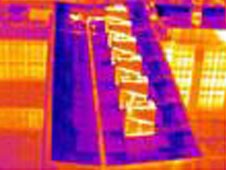

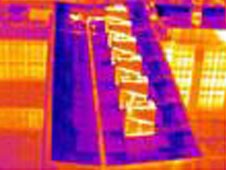

3. Mechanical Inspections

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

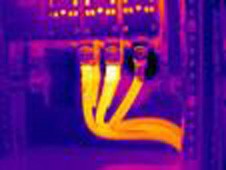

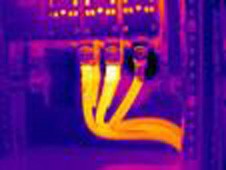

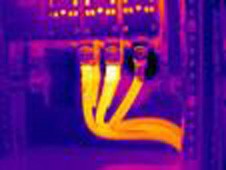

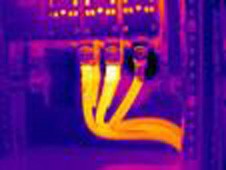

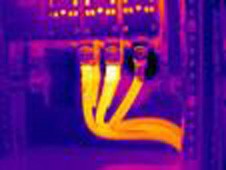

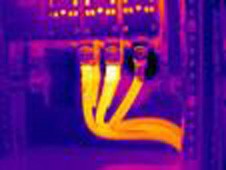

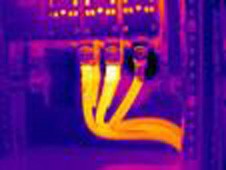

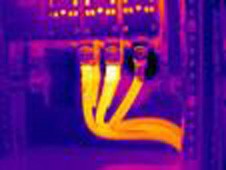

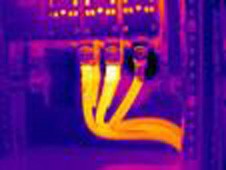

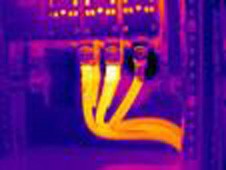

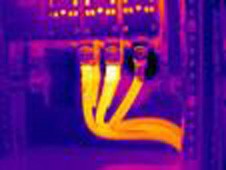

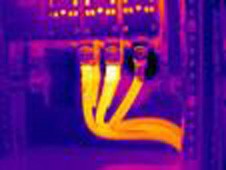

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel.

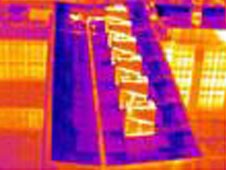

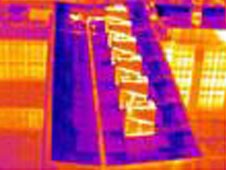

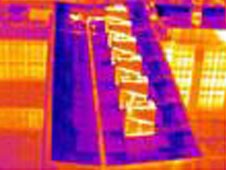

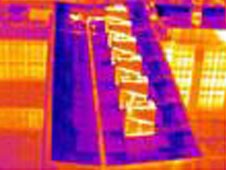

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

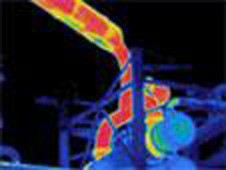

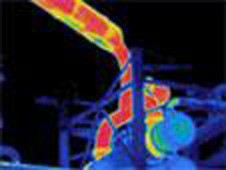

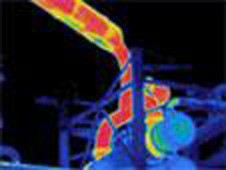

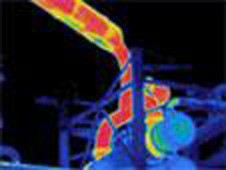

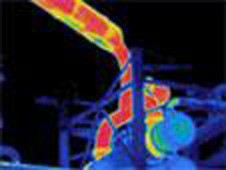

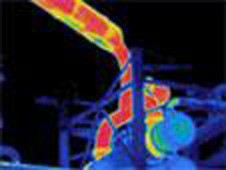

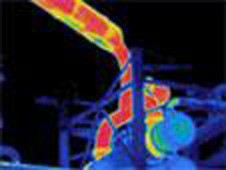

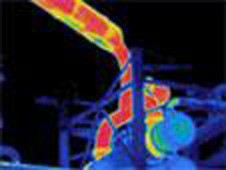

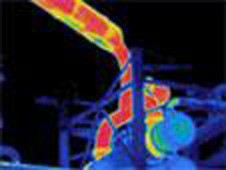

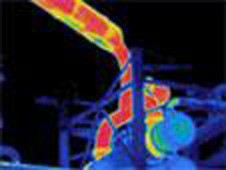

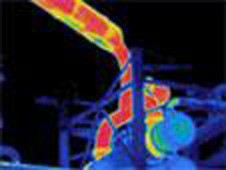

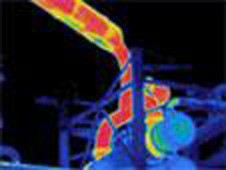

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems.

3. Mechanical Inspections

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems.

3. Mechanical Inspections

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems.

3. Mechanical Inspections

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

Cold Storage

Building Surveys

Mechanical Inspections

Electrical Inspections

Environmental Inspections

Research & Development

Industrial Inspections

Marine Inspections

Roof Surveys

PetroChem Inspections

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

1. Cold Storage

By their very nature, Cold Storage facilities have large running costs, mostly associated with electricity charges.

Looking towards conservation and energy saving makes financial sense in this world of increasing energy costs.

We can help to highlight areas of missing/poor insulation, wrongly functioning cooling systems, faulty electrical apparatus and lighting surveys.

2. Building Inspections

Our Thermographic Survey's monitor a buildings heating, ventilation and air conditioning systems and identifies the areas where energy is being wasted, saving you money.The construction of a building can leave behind their fair share of hidden problems. The development of Thermography has become the best fault finding tool.

Mechanical equipment can and does fail and often without any prior warning. Failure can cost thousands in the wages, lost production and delayed orders and that isn't including the cost of the repair or replacement work.

Using the maximum machine running time combined with poor maintenance, equipment can fail there may not be spare parts available.

3. Mechanical Inspections

4. Electrical Inspections

Thermal Imaging is great for Electrical Safety Inspections. In both domestic and commercial circumstances, it is able to identify connections or overloaded components in electrical areas. Electrical faults can lead to major failures with high costs.

Surveys are conducted whilst your equipment is working and under load. Any faults will be quickly located to save businesses money. Some insurance companies can offer discounts to regular Thermo graphic Surveying Programs.

5. Environmental Monitoring

If you monitor any potential harmful leaks to the environment then we have a solution for you. Our thermal imaging can monitor the following areas quickly and accurately than current conventional monitoring techniques:

6. Research & Development

Thermal imaging can be a great way to test anything that goes through a research and development process. We use state of the art software and cameras to detect the smallest differences in temperature over a very large scale.

We capture frames and these are stored in frames at real time that allows for very detailed and extensive analysis to take place.

7. Industrial Inspections

Infra-red inspections are a cost effective way of protecting assets. They are a valuable addition to any predictive maintenance programme. Any area can be inspected where heat or cold can be an issue.

Electrical fires are representative of 20% of large-scale fire incidents and 40% of fire loss insurance costs in industry. Accidents are commonly caused by weakened isolations, loose connections, mechanical damage and obstructed cooling.

8. Marine Inspections

Marine environments such as merchant vessels need to be reliable and safe at all times.

We are able to carry out an efficient thermo graphic inspection on any vessel. We can identify any problems and ensure they are dealt with quickly and efficiently without any interruption to your schedule. The inspection will analyse the seaworthiness of a vessel. This will give you the confidence in your marine vessel for complete safety.

9. Roof Surveys

Thermal imaging is a cost effective way of evaluating the condition of roof systems. Water damaged roofing can lead to major structural damage and deterioration of structures close to the leak. Identifying an exact location will help to choose the right method for repair.

10. PetroChem Inspections

Our PetroChem inspections cover pipe works, insulation, valves, critical systems, very high temperatures, zero tolerance for equipment failure and high output demand pressures on equipment.

We survey vast amounts of pipelines that are critical using Thermography technology. We will disrupt you as little as possible.

Cold Storage

Building Surveys

Mechanical Inspections

Electrical Inspections

Environmental Inspections

Cold Storage

Building Surveys

Mechanical Inspections

Electrical Inspections

Environmental Inspections

Research & Development

Industrial Inspections

Marine Inspections

Roof Surveys

PetroChem Inspections

Research & Development

Industrial Inspections

Marine Inspections

Roof Surveys

PetroChem Inspections

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

Thermographic Inspection Services Leader, Worldwide

Thermographic Inspection Services Leader, Worldwide

As well as racking inspections, Safety Survey carry out all types of specialist services. Our services include VOC leak detection, Thermographic Inspections and Compressed Air Leak Surveys. Below we have detailed descriptions of all the specialist services we provide. If you would like more information on our racking inspection services then please contact us with your requirements.

As well as racking inspections, Safety Survey carry out all types of specialist services. Our services include VOC leak detection, Thermographic Inspections and Compressed Air Leak Surveys. Below we have detailed descriptions of all the specialist services we provide. If you would like more information on our racking inspection services then please contact us with your requirements.

Specialist Services - In partnership with IRT Consult

Specialist Services - In partnership with IRT Consult

VOC Leak Detection

VOC Leak Detection

VOC Leak Detection

Fugitive gas emissions can cost companies' time and money to find. Annually vast sums of revenue are invested in identifying these leaks as part of companies LDAR (Leak Detection and Repair) programmes. The majority of the mass emissions come from a small number of components with high leak rates.

Safety Survey are able to use thermal imaging cameras and equipment to find the location of a potential leak. On average we can monitor 3000 plus components per hour. This offers considerable savings when it is compared to the 500 components being monitored daily using the traditional "Hand-Held Sniffer" technology. We use a Flir Systems ThermaCAM GasFindIR HSX camera to detect any potential leaks by producing thermal imaging.

Leaks can be detected in:

Fugitive gas emissions can cost companies' time and money to find. Annually vast sums of revenue are invested in identifying these leaks as part of companies LDAR (Leak Detection and Repair) programmes. The majority of the mass emissions come from a small number of components with high leak rates.

Safety Survey are able to use thermal imaging cameras and equipment to find the location of a potential leak. On average we can monitor 3000 plus components per hour. This offers considerable savings when it is compared to the 500 components being monitored daily using the traditional "Hand-Held Sniffer" technology. We use a Flir Systems ThermaCAM GasFindIR HSX camera to detect any potential leaks by producing thermal imaging.

Leaks can be detected in:

Fugitive gas emissions can cost companies' time and money to find. Annually vast sums of revenue are invested in identifying these leaks as part of companies LDAR (Leak Detection and Repair) programmes. The majority of the mass emissions come from a small number of components with high leak rates.

Safety Survey are able to use thermal imaging cameras and equipment to find the location of a potential leak. On average we can monitor 3000 plus components per hour. This offers considerable savings when it is compared to the 500 components being monitored daily using the traditional "Hand-Held Sniffer" technology. We use a Flir Systems ThermaCAM GasFindIR HSX camera to detect any potential leaks by producing thermal imaging.

Leaks can be detected in:

Tank cars

Pipelines

Process plant

Compressor Sites

Refineries

Chemical Plants

Power Generation Plants

Tank Farms

Gas Transmission Pipelines

Manufacturing Facilities

LNG Transport Ships

Get in touch today for your accurate quotation as each site is different. We will gladly discuss your project with you in terms of price, availability, application and duration.

Get in touch today for your accurate quotation as each site is different. We will gladly discuss your project with you in terms of price, availability, application and duration.

Chemical Plants

Power Generation Plants

Tank Farms

Gas Transmission Pipelines

Manufacturing Facilities

LNG Transport Ships

Chemical Plants

Power Generation Plants

Tank Farms

Gas Transmission Pipelines

Manufacturing Facilities

LNG Transport Ships

Tank cars

Pipelines

Process plant

Compressor Sites

Refineries

Tank cars

Pipelines

Process plant

Compressor Sites

Refineries

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

Compressed Air Leak Surveys

Compressed Air Leak Surveys

Compressed Air Leak Surveys

One of the most costly utilities in facilities today is compressed air. We are unfortunately aware that many plants are operating with vast leakage rates and these can be very costly. A leak inspection program and repair can vastly reduce any excessive cost of energy.

One of the most costly utilities in facilities today is compressed air. We are unfortunately aware that many plants are operating with vast leakage rates and these can be very costly. A leak inspection program and repair can vastly reduce any excessive cost of energy.

Leak Inspection & Repair

A Detailed Report

Leak Inspection & Repair

One of the most costly utilities in facilities today is compressed air. We are unfortunately aware that many plants are operating with vast leakage rates and these can be very costly. A leak inspection program and repair can vastly reduce any excessive cost of energy.

One of the most costly utilities in facilities today is compressed air. We are unfortunately aware that many plants are operating with vast leakage rates and these can be very costly. A leak inspection program and repair can vastly reduce any excessive cost of energy.

Leak Inspection & Repair

Leak Inspection & Repair

A Detailed Report

A Detailed Report

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

Surveys of Compressed Air Leaks can save money by assisting in the reduction of excessive energy costs. A thorough survey of your site will be conducted by our technicians and they will locate any air leaks, then provide a detailed report that includes precise cost per leak, photographs, and recommendations for the repairs required. We ensure that our surveys are carried out with no interference to your business as large areas of plant can be surveyed in one day.

What The Survey Involves

What The Survey Involves

Ultrasonic sensing equipment is deployed to carry out the surveys and follow the format below:

Ultrasonic sensing equipment is deployed to carry out the surveys and follow the format below:

1. We will observe your plant and find any misuse of compressed air such as valves left wide open also determining the best route for inspection.

2. Ultrasonic sensing equipment is used to locate leaks, each leak is identified, tagged and documented.

3. Once complete we have a debrief meeting with the facilities/plant manager to discuss our findings from the survey.

4. A thorough report is made and this contains the information of each leak including its size, cost of leak and repair recommendations.

The report is normally issued within 4 days of survey completion.

1. We will observe your plant and find any misuse of compressed air such as valves left wide open also determining the best route for inspection.

2. Ultrasonic sensing equipment is used to locate leaks, each leak is identified, tagged and documented.

3. Once complete we have a debrief meeting with the facilities/plant manager to discuss our findings from the survey.

4. A thorough report is made and this contains the information of each leak including its size, cost of leak and repair recommendations.

The report is normally issued within 4 days of survey completion.

1. We will observe your plant and find any misuse of compressed air such as valves left wide open also determining the best route for inspection.

2. Ultrasonic sensing equipment is used to locate leaks, each leak is identified, tagged and documented.

3. Once complete we have a debrief meeting with the facilities/plant manager to discuss our findings from the survey.

4. A thorough report is made and this contains the information of each leak including its size, cost of leak and repair recommendations.

The report is normally issued within 4 days of survey completion.

What The Survey Involves

What The Survey Involves

Ultrasonic sensing equipment is deployed to carry out the surveys and follow the format below:

Ultrasonic sensing equipment is deployed to carry out the surveys and follow the format below:

FAQs

What services does Safety Survey offer as warehouse safety specialists?

Why is racking inspection important for my company?

What types of inspections and training services are available?

How can Safety Survey help with compliance with legal requirements and insurers?

When should I consider a racking inspection according to the SEMA code of practice?

Can Safety Survey assist in setting up internal racking checks?

What specialist services does Safety Survey provide?

How often should racking inspections be conducted to ensure safety?

How can I benefit from Safety Survey's expert racking inspections?

How can I schedule an inspection or training session with Safety Survey?

What services does Safety Survey offer as warehouse safety specialists?

Why is racking inspection important for my company?

What types of inspections and training services are available?

How can Safety Survey help with compliance with legal requirements and insurers?

When should I consider a racking inspection according to the SEMA code of practice?

Can Safety Survey assist in setting up internal racking checks?

What specialist services does Safety Survey provide?

How often should racking inspections be conducted to ensure safety?

How can I benefit from Safety Survey's expert racking inspections?

How can I schedule an inspection or training session with Safety Survey?

What services does Safety Survey offer as warehouse safety specialists?

Why is racking inspection important for my company?

What types of inspections and training services are available?

How can Safety Survey help with compliance with legal requirements and insurers?

When should I consider a racking inspection according to the SEMA code of practice?

Can Safety Survey assist in setting up internal racking checks?

What specialist services does Safety Survey provide?

How often should racking inspections be conducted to ensure safety?

How can I benefit from Safety Survey's expert racking inspections?

How can I schedule an inspection or training session with Safety Survey?